Bottom Pouring Set

Bottom pouring set is a mixture of fractions of various refractory materials that can be given any shape. It is a specialized process that requires obtaining fractions of plastic and non plastic fire clays and then pugging them to have a homogeneous mixture. This mixture is cold pressed to get the desired shape.

Afterwards, this shape is heated to a very high temperature of 1300 degrees Centigrade. Galaxy Refractories is considered the best among all bottom pouring set exporters, suppliers and manufacturers in Indian country because of high quality and top class performance. Our export market is Kenya, Tanzania, Gabon, Mauritius, Sri Lanka, Angola, Nigeria, UAE, Turkey and other countries also.

Galaxy Refractories makes two main types of Bottom Pouring Sets.

- Set having 30% alumina

- Set having 40% alumina

However, we have the capability to make these sets with higher or lower alumina percentage as per specifications and requirements of our clients.

Special features of BP Set made by us :

- Can withstand thermal shocks of large dimensions

- Male and female combinations fit accurately

- Perfect size and shape

- No deposition of carbon

- Prevent failure of bricks at high temperature

- Longevity of lining bricks increased

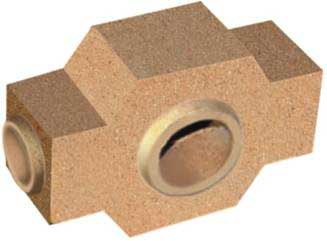

Some of the common shapes of BP sets made by us

- Side runner

- Plate

- Center bricks

- Funnel

- Main runner end

- Side runner

- Side runner end

- Sleeve

Bottom pouring sets made by Galaxy Refractories are loved by its clients as they show no signs of wear and tear even at very high temperatures. The physical and chemical properties of these sets are as per ISI specifications